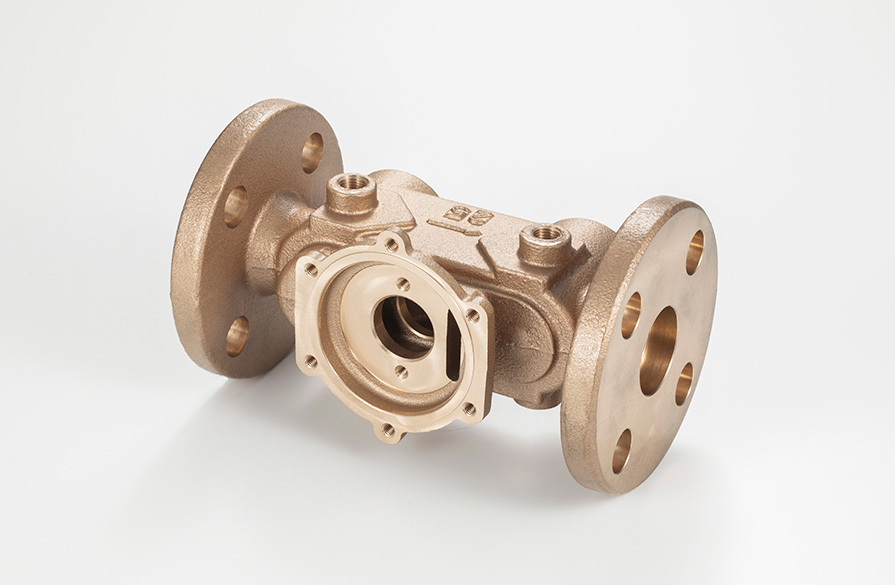

Bronze Castings

High-quality castings produced by accumulated experience and advanced technology

Combining the casting technology we have cultivated since our founding with the latest technology, we stably manufacture high-quality copper alloy castings to support the foundations of society in a variety of fields.

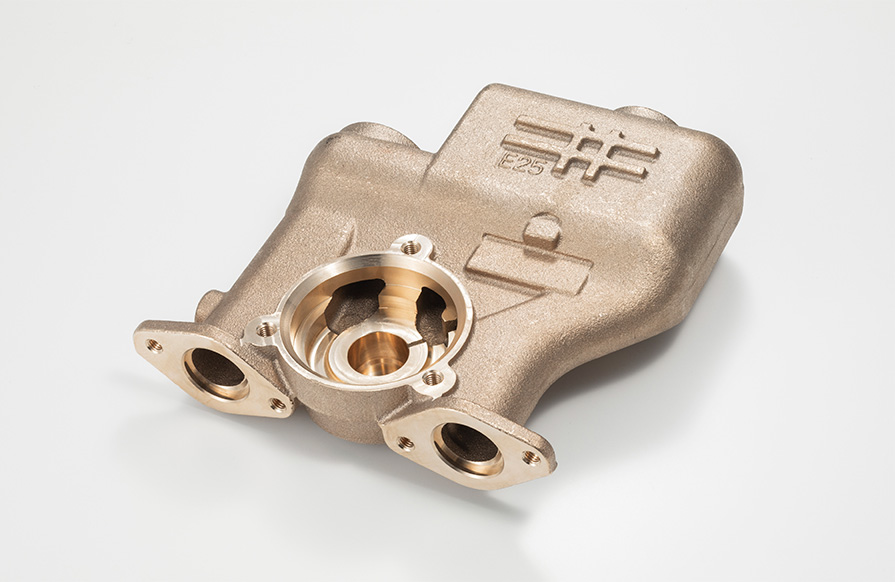

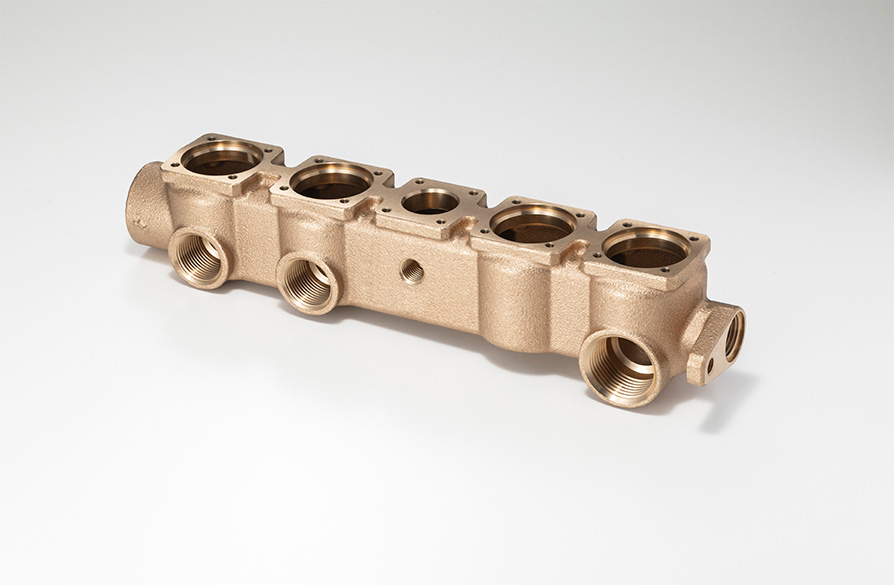

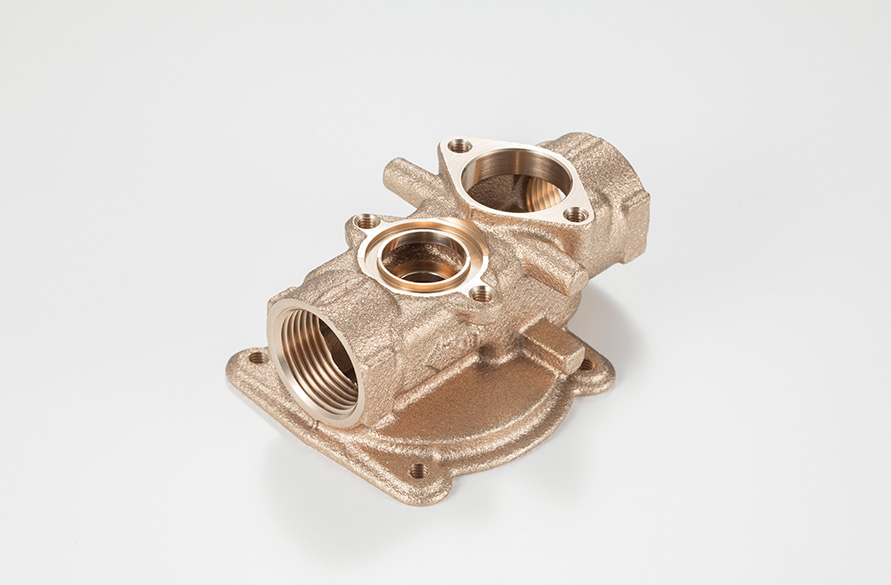

Our cast products are used in many water-related parts, such as water meters, water pumps, pipe fittings, and pressure reducing valves. In addition, our bearings, which take advantage of their superior sliding characteristics, are used as internal parts in construction and industrial machinery, and play an important role in unseen places.

PRODUCT EXAMPLES

- Water meter case

- Pressure reducing valve body

- Pump casing

- Impeller

- Valve body

- Pipe fittings

- Wire fittings

- Bearing

Our Strengths when it Comes to Bronze Castings

①Integrated Production System

Each process is completed in house, ensuring stable supply with short delivery times and low costs.

②A Wide Variety of Compatible Materials

Applicable to various types of copper alloy materials.

Supported materials

| bronze | CAC401、CAC406、CAC408 |

| lead-free bronze | CAC902、CAC906 |

| lead bronze | CAC603 |

| high-strength brass | CAC301~304 |

| aluminum bronze | CAC502 |

| phosphor bronze | CAC701、CAC702 |

③One of Japan’s leading production capacities

The company has one of the highest production capacities in Japan (160 tons/month) and can flexibly handle lots ranging from tens of pieces to tens of thousands of pieces.

④Introduction of the latest technology

Defective countermeasures using hot water flow and solidification simulation, improved inspection accuracy using AI visual inspection equipment, and reverse engineering using 3D scanners.

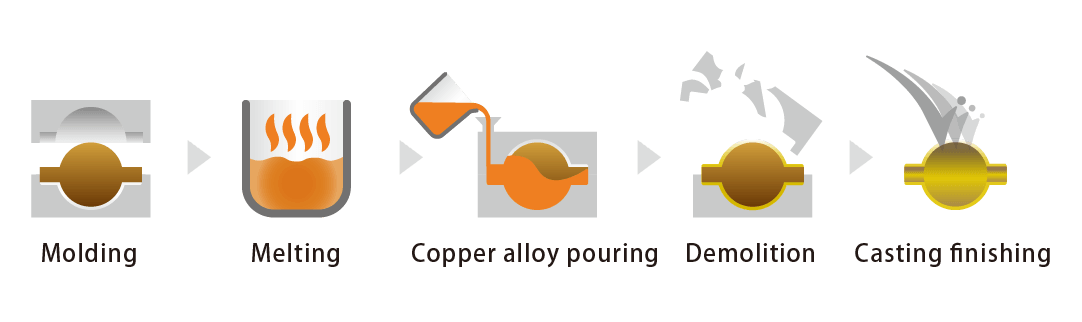

Manufacturing Engineering

On small screens, the figure can be scrolled to the right

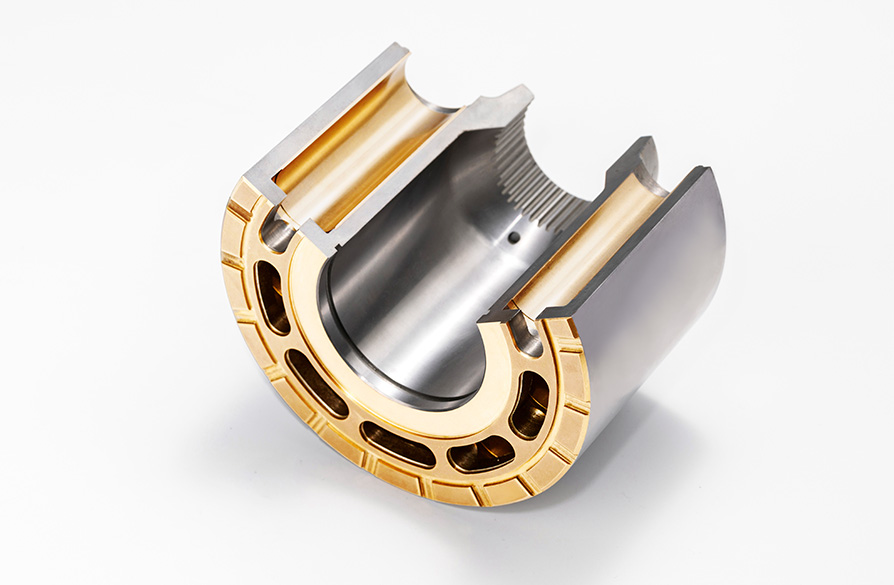

Bimetal Basics

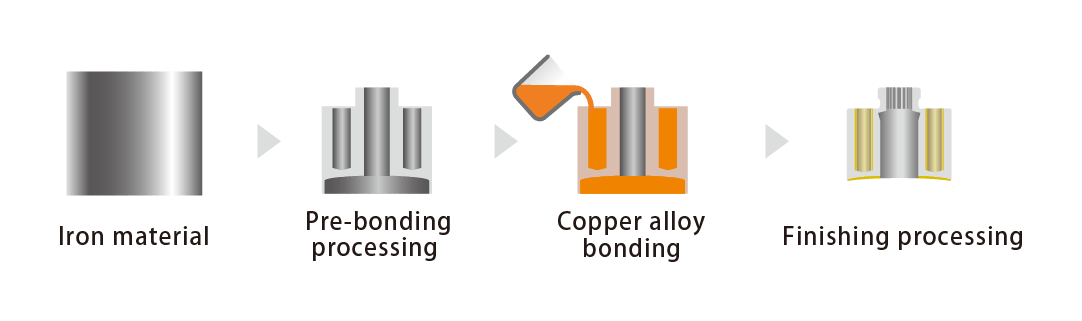

A Composite Material Which Takes Advantage of the Strength of Iron Alloys and the Bearing Properties of Copper

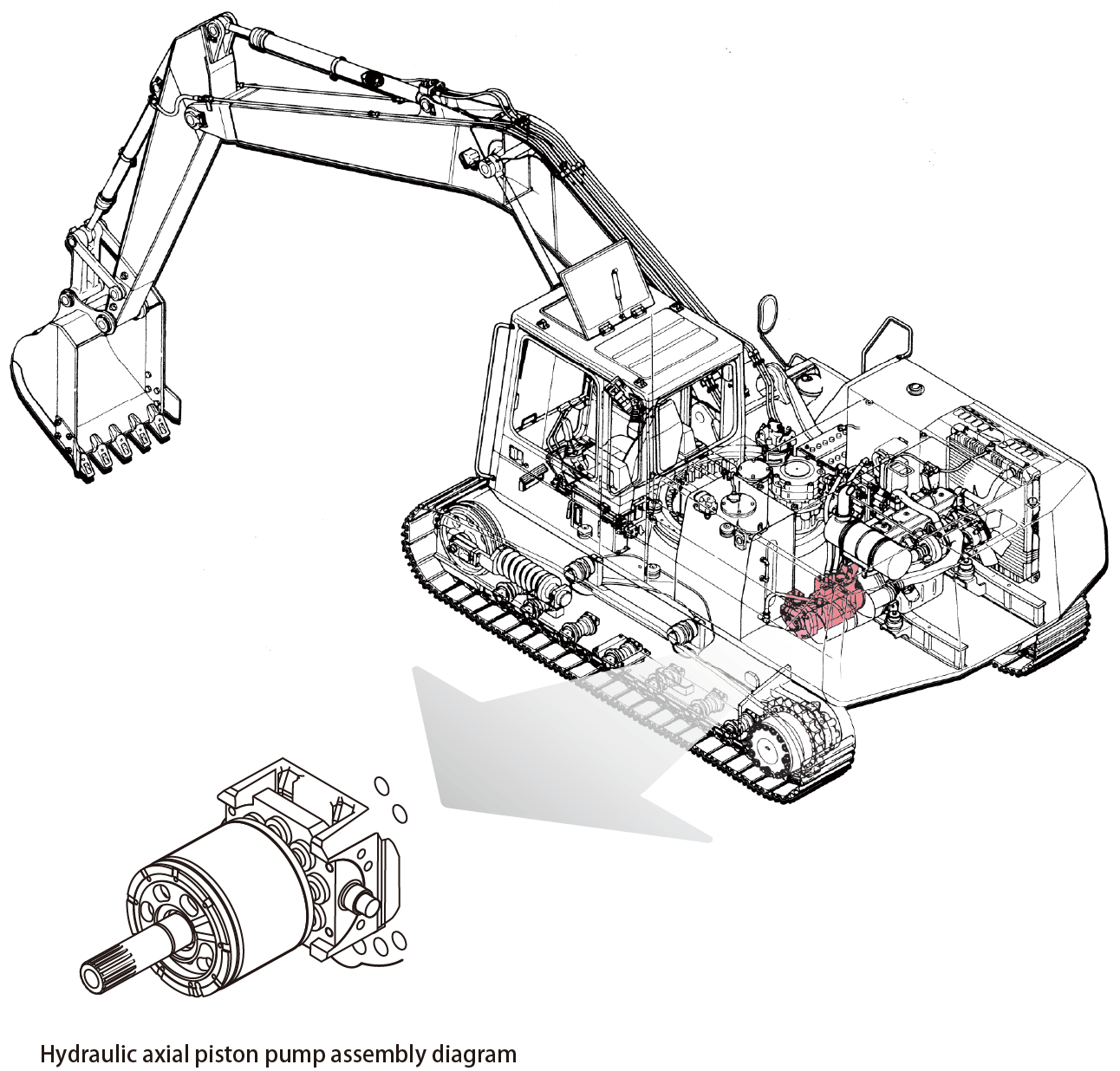

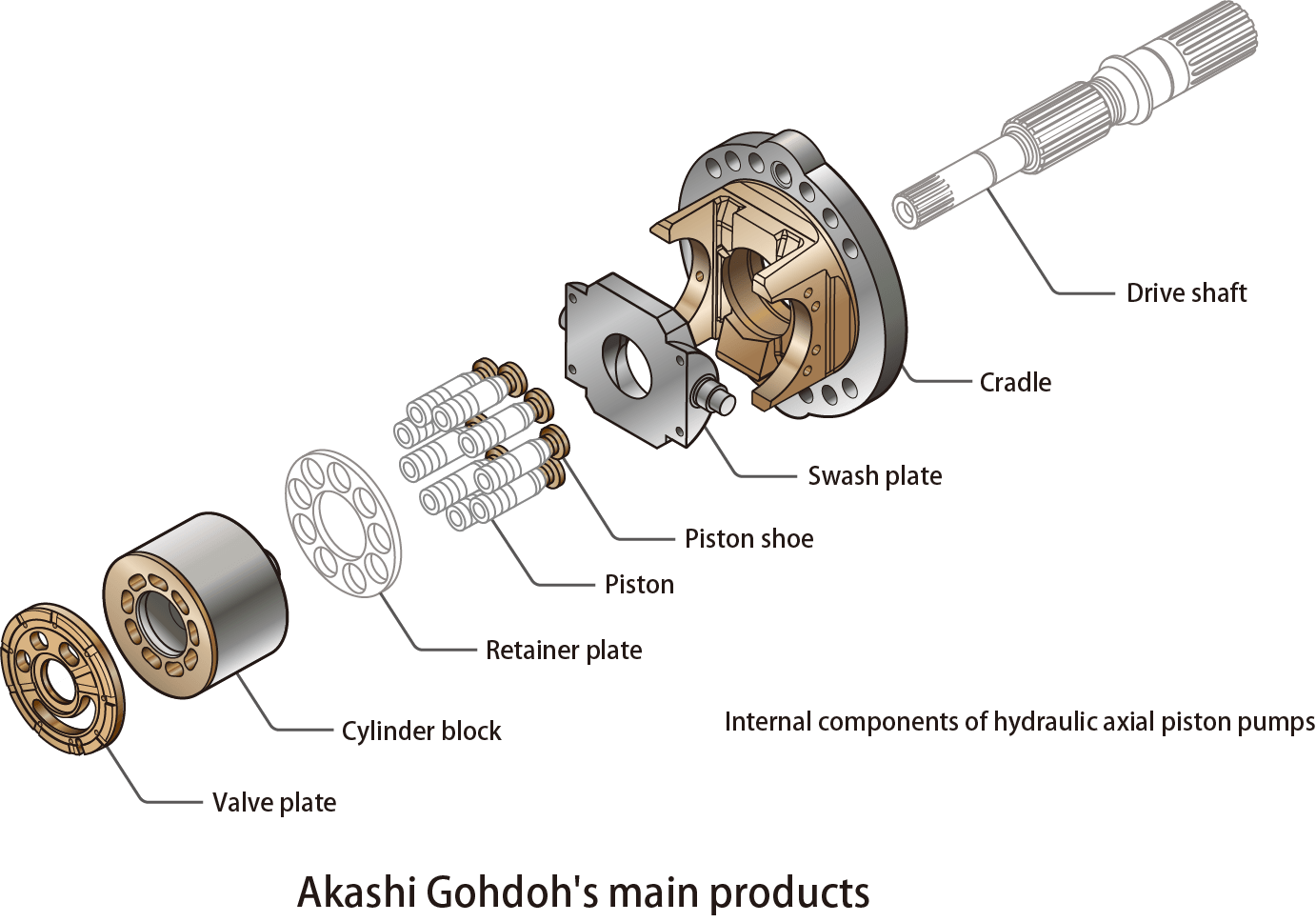

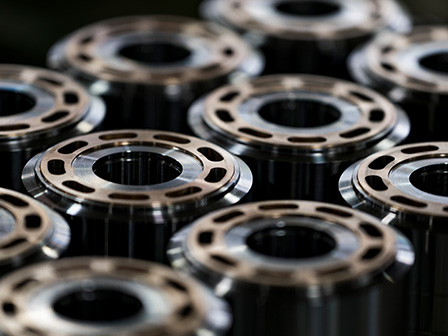

Our unique bonding process enables us to produce bimetal products which combine the high strength of iron alloys and the bearing qualities of bronzes. The bronzes are firmly bonded to the iron-based materials. High-pressure hydraulic pumps are literally the pumping hearts of construction equipment, and our cylinder blocks are used in them around the world.

PRODUCT EXAMPLES

- Cylinder block

- Valve Plate

- Cradle

- Rocker Cam

- Shoe

- Piston

- connecting rod

Applications

Our Strengths when it Comes to Bimetal Products

①High strength and excellent bearing performance

The high bonding strength of ferrous materials and copper alloys allows for safe use under extremely severe conditions of high speed and high pressure.

②Precision machining

Precision machining down to the micron level.

③Material Compatibility

Depending on the application, a wide variety of iron alloys and bronzes can be used.

Applicable Materials

| Base metals | Special steel (SCM440), carbon steel (S45C), cast iron (FC, FCD), etc. |

| Copper alloys | Lead bronze (CAC603, LBA), lead-free bronze (pearlite bronze PBX), aluminum bronze (AlBC: for MIG welding) |

Manufacturing Engineering

On small screens, the figure can be scrolled to the right

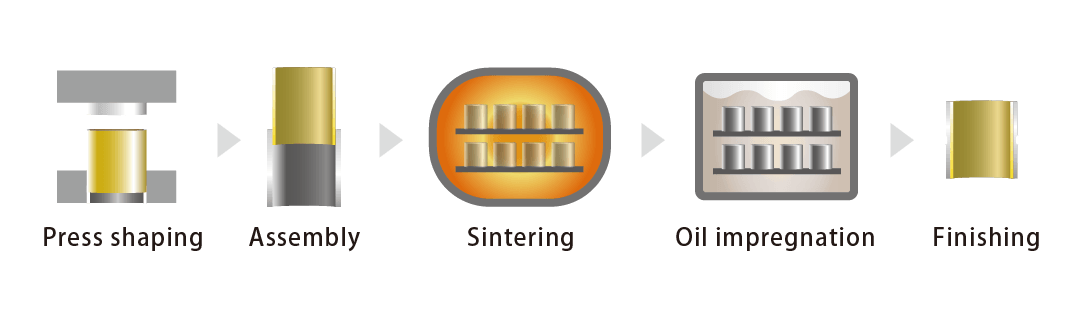

Oil Impregnated Powder Sintered Bearings

Self-lubricating bearing productsd Self-lubricating

BMRC bushings, our mainstay sintered products, are bimetallic oil-impregnated bearings that combine the strength of back metal with excellent self-lubricating properties by sinter-joining copper alloy powder to the inner diameter of iron-based pipe material and impregnating it with a special lubricant.

Manufacturing Engineering

On small screens, the figure can be scrolled to the right

Developed Products

Pearlite Bronze (PBX), a Bronze-based Lead-free Material with Superior Sliding Properties

The lead-free copper alloy “Pearlite Bronze (PBX)” was developed over a period of more than 10 years in response to the increasing demand for lead-free sliding parts.

PBX contains no lead at all (less than 0.1%) and has the same sliding properties as leaded bronze. It can be used as a substitute for leaded bronze (CAC603) in sand casting bearing products and bimetallic products.

Patented in Japan (Patent No. 4806823) and 7 countries overseas.

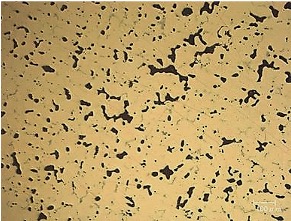

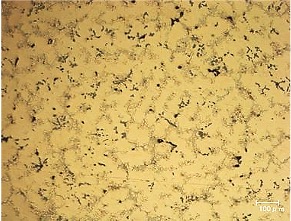

Microstructure

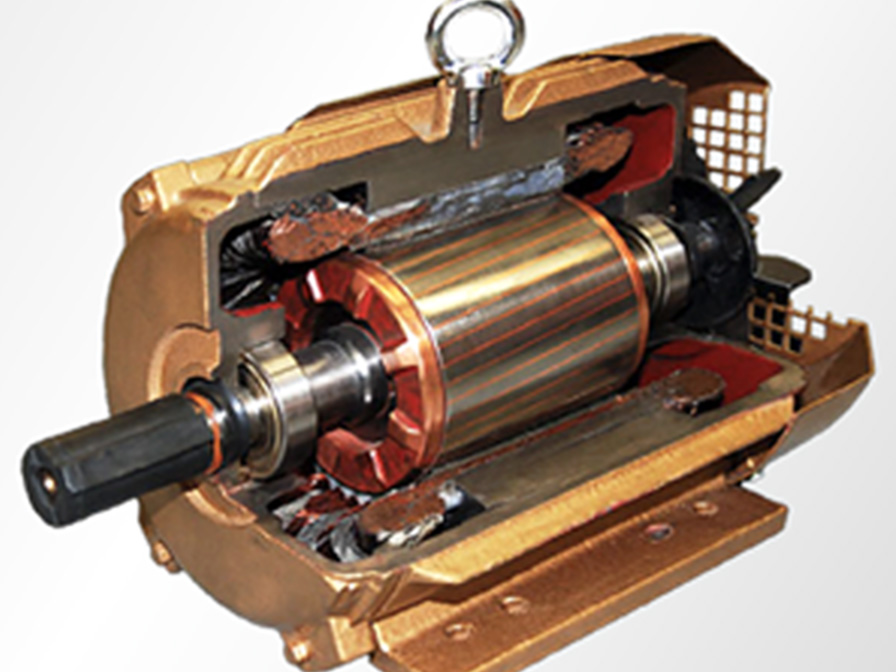

Die-cast pure copper rotor

For the first time in Japan, we have established production technology for die-cast pure copper rotors for high-efficiency motors.

Replacing aluminum with pure copper for the secondary conductor of motors is expected to improve efficiency by 1.5 to 3%. Advanced melting technology, temperature control of molds, and optimum method design have overcome the challenges of pure copper die casting and significantly improved productivity compared to assembly brazed pure copper rotors.