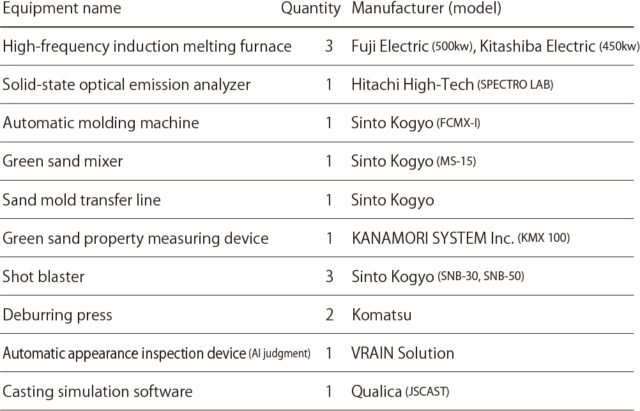

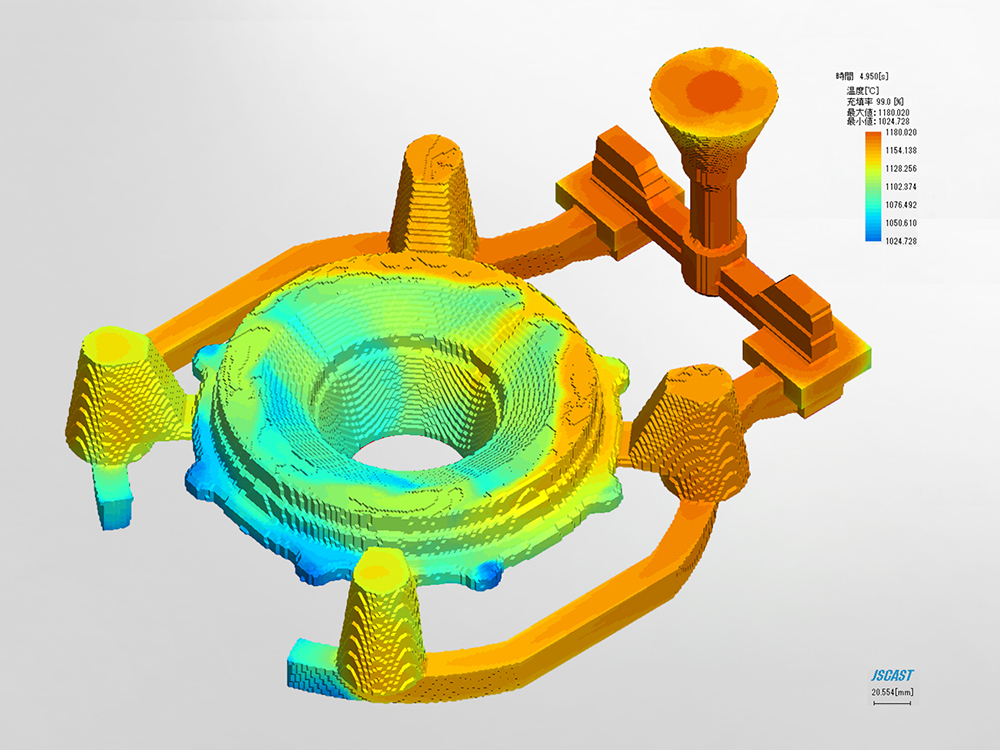

Copper alloy casting line

The highly productive casting line uses an automatic molding machine to create high-precision molds, and skilled workers pour molten metal melted by a high-frequency induction furnace. Copper alloy casting line

High-frequency induction melting furnace(Fuji Electric 500kw, Kitashiba Electric 450kw) 3units

Solid-state optical emission analyzer(Hitachi High-Tech SPECTRO LAB)1unit

Automatic molding machine (Sinto Kogyo FCMX-I) 1unit

Green sand mixer (Sinto Kogyo MS-15) 1unit

Sand mold transfer line(Sinto Kogyo) 1unit

Green sand property measuring device(Kanamori system Inc. KMX100)1unit

Shot blaster(Sinto Kogyo SNB-30, SNB-50) 3units

Deburring press(Komatsu) 2units

Automatic appearance inspection device AI judgment(Vrain Solution)1unit

Casting simulation software(Qualica JSCast)1unit

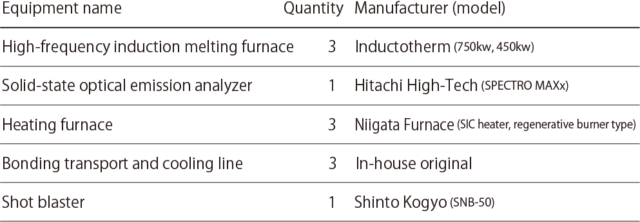

Bimetal bonding line

A bonding line that pours copper alloy into iron base metal to join iron and copper. This is an in-house production line filled with one-of-a-kind technology.

High-frequency induction melting furnace(Inductotherm 750kw, 450kw) 3units

Solid-state optical emission analyzer(Hitachi High-Tech SPECTRO MAXx) 1unit

Heating furnace(Niigata Furnace SIC heater, regenerative burner type) 3units

Bonding transport and cooling line(In-house original) 3units

Shot blaster(Shinto Kogyo SNB-50) 1unit

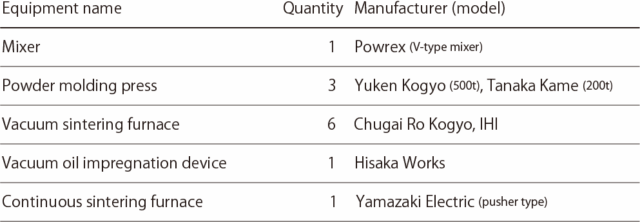

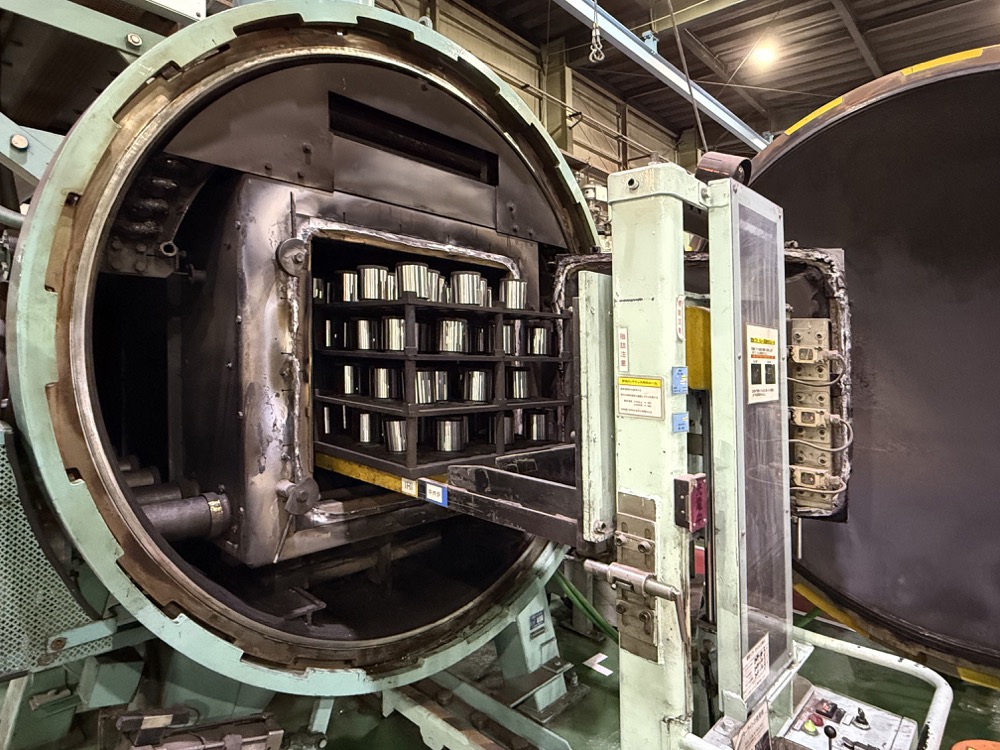

Powder sintering line

Oil-impregnated bearings, our main product, are manufactured by press molding powder, sintering it in a vacuum sintering furnace, and sinking oil into it in an oil-impregnating device.

Mixer(Powrex V-type mixer) 1unit

Powder molding press(Yuken Kogyo 500t, Tanaka Kame 200t) 3units

Vacuum sintering furnace(Chugai Ro Kogyo, IHI) 6units

Vacuum oil impregnation device(Hisaka Works) 1unit

Continuous sintering furnace(Yamazaki Electric pusher type) 1unit

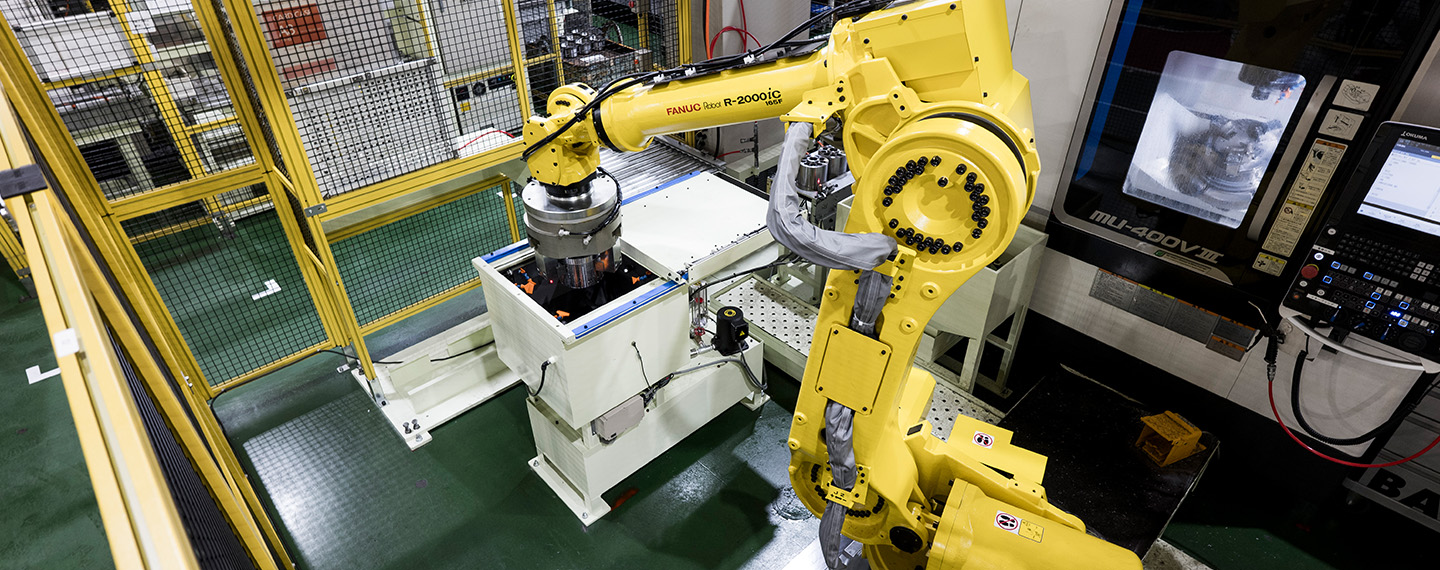

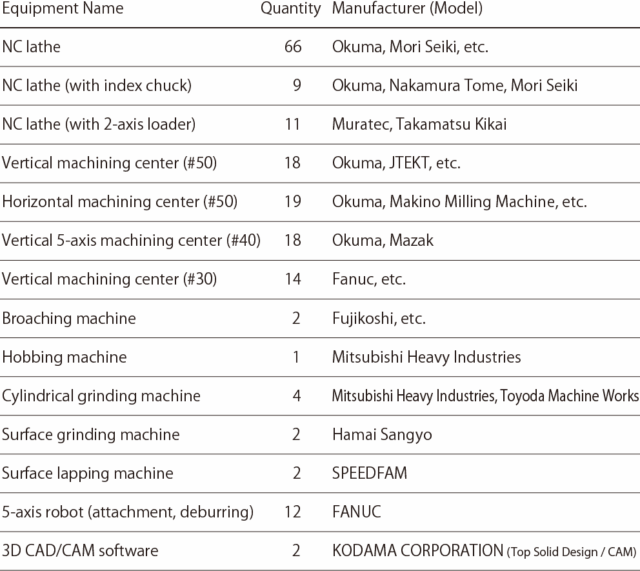

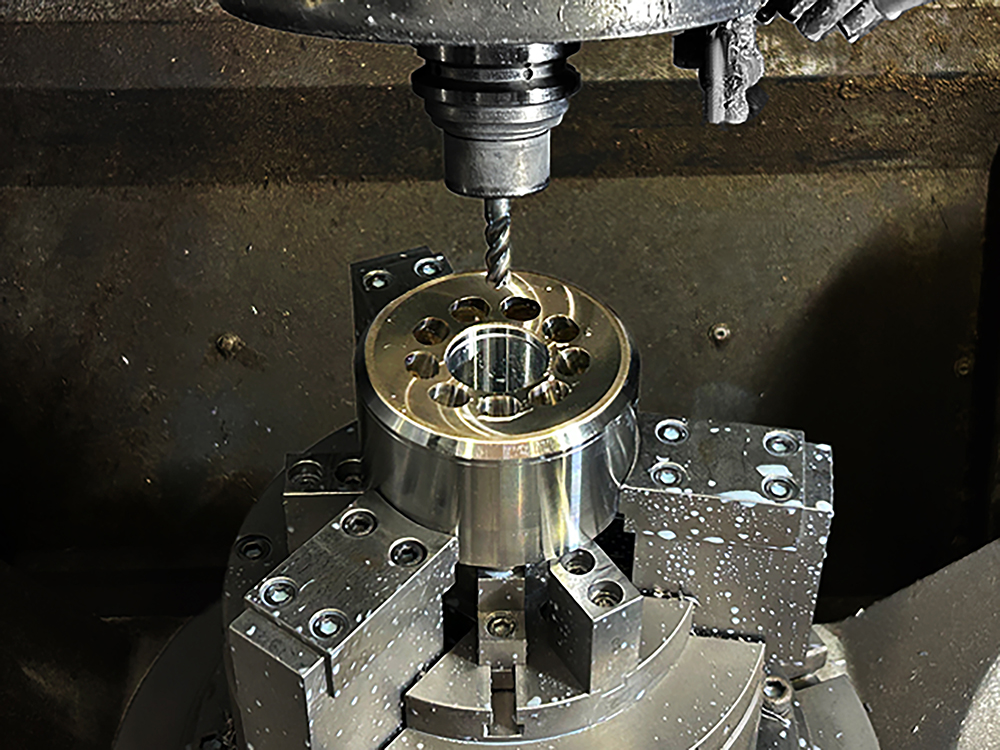

Machining line

We perform precision machining of materials produced by the forging division. Automation with robots and loaders contributes to cost reduction.

NC lathe(Okuma, Mori Seiki, etc.) 66units

NC lathe with index chuck (Okuma, Nakamura Tome, Mori Seiki) 9units

NC lathe with 2-axis loader(Muratec, Takamatsu Kikai) 11units

Vertical machining center #50(Okuma, JTEKT, etc.) 18units

Horizontal machining center #50(Okuma, Makino Milling Machine, etc.) 19units

Vertical 5-axis machining center #40(Okuma, Mazak) 18units

Vertical machining center #30(Fanuc, etc.) 14units

Broaching machine (Fujikoshi, etc.) 2units

Hobbing machine (Mitsubishi Heavy Industries) 1unit

Cylindrical grinding machine (Mitsubishi Heavy Industries, Toyoda Machine Works) 4units

Surface grinding machine(Hamai Sangyo) 2units

Surface lapping machine(SPEEDFAM) 2units

5-axis robot attachment, deburring(FANUC) 12units

3D CAD/CAM software(KODAMA CORPORATION Top Solid Design / CAM) 2units

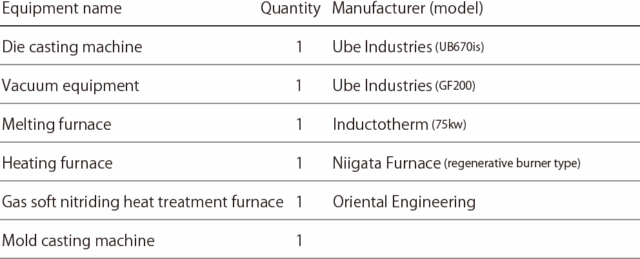

Facilities for Technology Development

Develop new copper alloy materials and test new manufacturing methods. Equipment for Technology Development

Die casting machine (Ube Industries UB670is) 1unit

Vacuum equipment (Ube Industries GF200) 1unit

Melting furnace (Inductotherm 75kw) 1unit

Heating furnace (Niigata Furnace regenerative burner type) 1unit

Gas soft nitriding heat treatment furnace (Oriental Engineering) 1unit

Mold casting machine 1unit