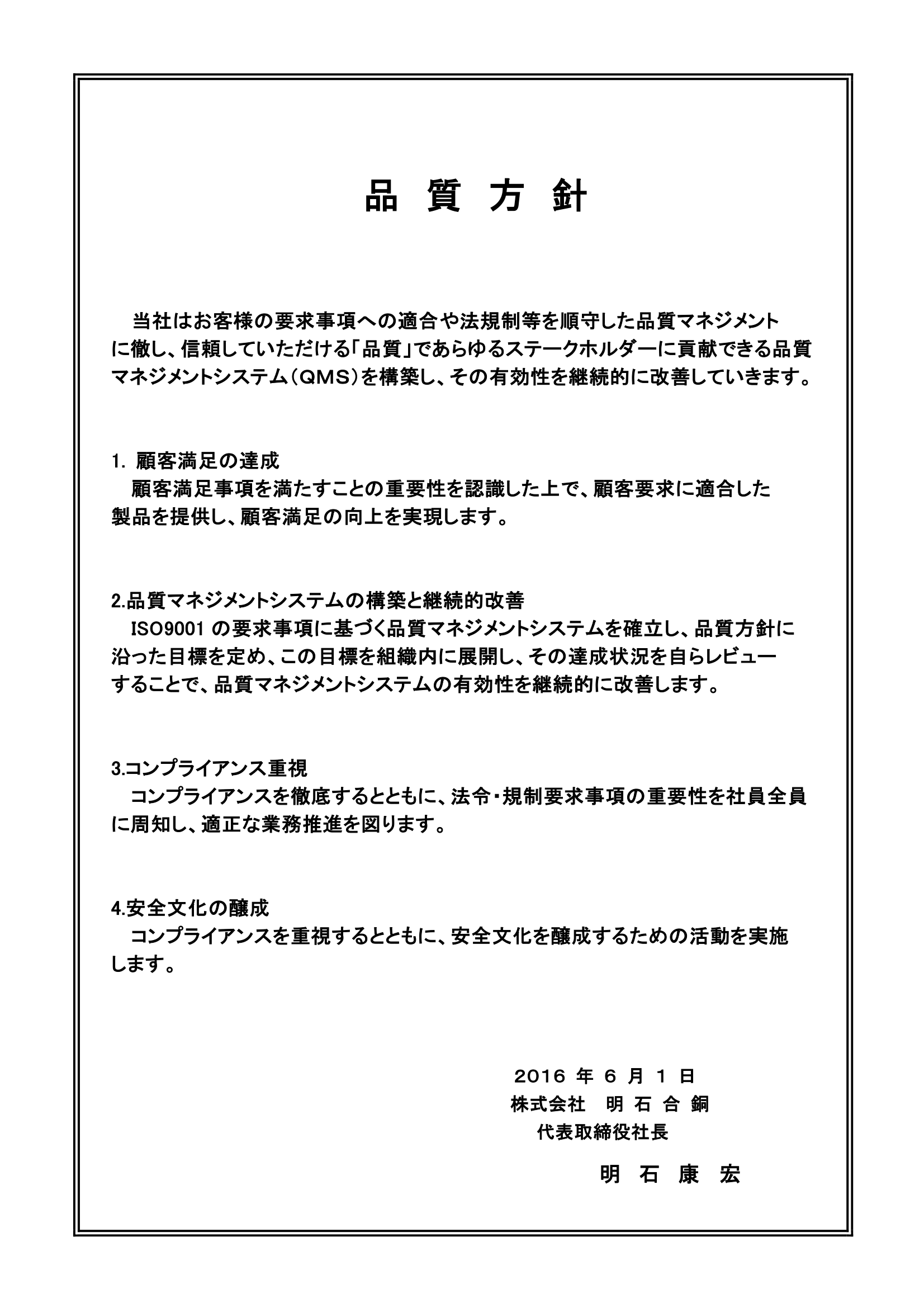

Akashi Gohdoh has acquired ISO 9001:2015 certification for its quality management system, ensuring a stable supply of high-quality products that satisfy our customers. Products manufactured according to the procedures specified in the work standards are inspected at each process, and a system has been established to prevent defective products from being passed on to subsequent processes. We will continue to strive for further quality improvement based on “human resource development” and “continuous improvement.

ISO9001certificate

Quality Policy

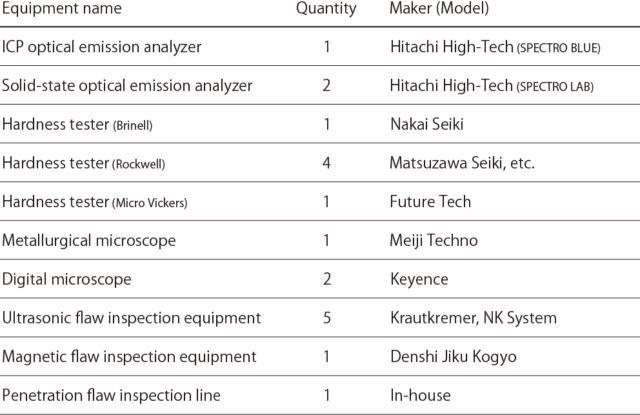

Inspection equipment

Material Inspection

ICP optical emission analyzer(Hitachi High-Tech Spectro Blue)1unit

Solid-state optical emission analyzer(Hitachi High-Tech Spectro Lab)2units

Hardness tester[Brinell](Nakai Seiki) 1unit

Hardness tester[Rockwell](Matsuzawa Seiki, etc.) 4units

Hardness tester[Micro Vickers](Future Tech) 1unit

Metallurgical microscope(Meiji Techno) 1unit

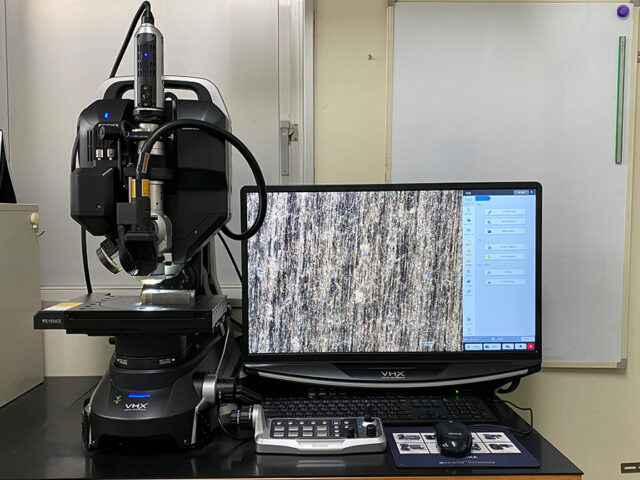

Digital microscope(Keyence) 2units

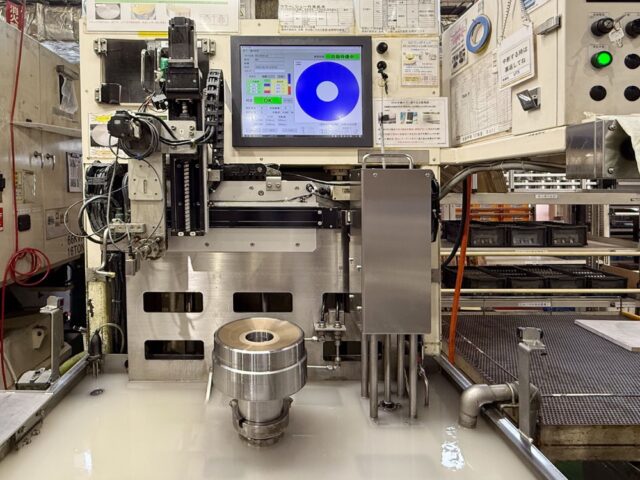

Ultrasonic flaw inspection equipment(Krautkremer, NK System) 5units

Magnetic flaw inspection equipment (Denshi Jiku Kogyo) 1unit

Penetration flaw inspection line(In-house) 1unit

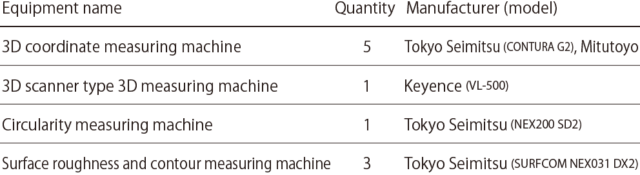

Dimensional Inspection

3D coordinate measuring machine(Tokyo Seimitsu CONTURA G2), Mitutoyo) 5units

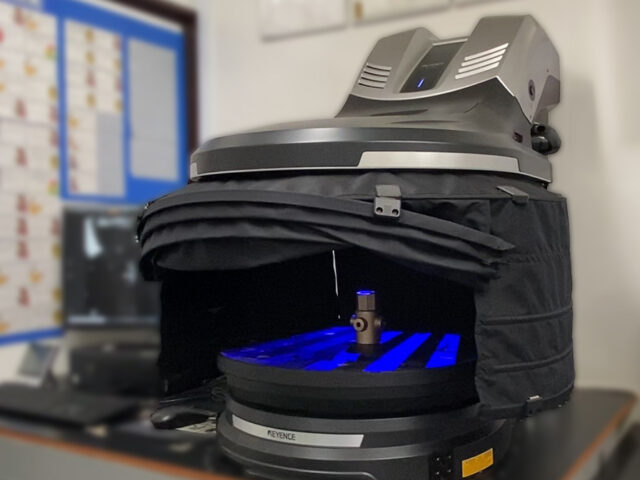

3D scanner type 3D measuring machine(Keyence VL-500) 1unit

Circularity measuring machine(Tokyo Seimitsu NEX200 SD2) 1unit

Surface roughness and contour measuring machine(Tokyo Seimitsu SURFCOM NEX031 DX2) 3units